THE LATEST HEAVY-DUTY H8-12XD MODELS FROM HYSTER® PROVIDE OPTIMAL VISIBILITY, STRENGTH AND RELIABILITY, MAKING HANDLING AND TRANSPORTATION EASIER THAN EVER.

EACH MODEL GIVES OUTSTANDING POWER AND RELIABILITY WITH FAST ATTACHMENT EXCHANGE AS WELL AS OPTIMUM VISIBILITY OF THE FORKS, THE ATTACHMENT, AND THE LOAD.

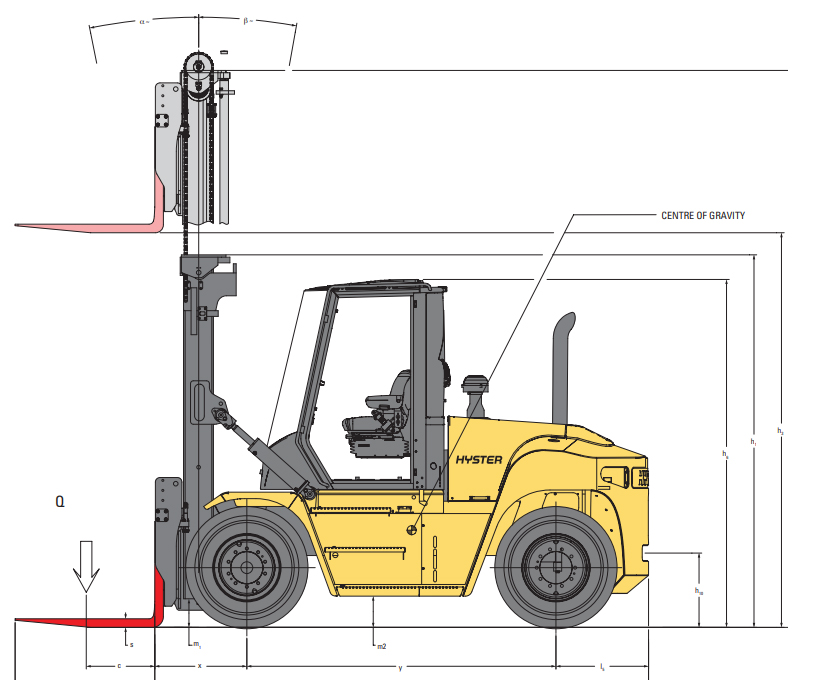

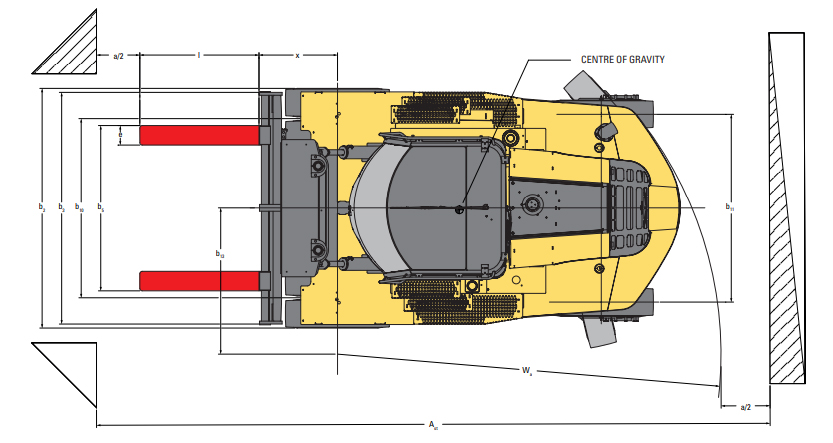

ROBUST FRAME AND MAST

The robust frame and wide drive axle provide rock solid stability and long-term durability when handling loads at full capacity. The trucks include two-stage masts with extended range of pin or hook type carriages. More space between mast channels gives enhanced visibility of the attachment and load. Intelligent design has increased the residual capacity on each truck by at least 400kg for the side shift pin type carriage. More space between mast channels gives enhanced visibility of the attachment and load as the chains are on the outside of the mast. Operators can see through and over the carriage which helps provide ideal levels of visibility for ground level and lorry bed height manoeuvres. Carriages have slimline top bars with an intelligently located valve block Reduced “lost load” centres: the more open design results in less weight on the carriage and gets the load closer to the truck.

ERGONOMIC CAB

The new ergonomically design high visibility cab puts greater productivity within easy reach. Equipped with an armoured glass top window, curved front and rear windows and steel doors with tempered glass, the new operator cab provides excellent all-around visibility. Inside the cab there is more space with the largest entry area in the industry, more control with a full-colour screen displaying performance data at the operator’s fingertips and more comfort with an exclusive lateral sliding seat, adjustable steering column and foot pedal, plus ergonomic controls.

CLASS-LEADING LIFTING AND TRAVEL SPEEDS

Thanks to the practical four-modes feature the trucks can achieve impressive lifting speed averages between 0.40m/s and 0.69m/s with full nominal capacity up to 6250mm. The heavy duty industrial use engine comes with a cast iron cylinder block and no HT (high tension) wires, distributor caps or rotors. Super quick glow plugs allow the engine to start quickly and reliably under cold conditions, the cold start device delivering a cleaner exhaust by advancing the fuel injection timing based on water temperature. Whilst emissions have been reduced by controlling fuel injection timing according to engine load.

New performance optimisation developments are included such as cooling on demand, load sensing hydraulics (power on demand), RPM management and alternate engine idle speed to help further reduce the total fuel consumption in most applications.